Mobile Inventory Management Software Redefines Real-time Data

November 10, 2023 - 11 minutes readInventory management on-the-go produces unexpected benefits.

When new technology in the 1980s moved inventory management from manual logs and punch cards to digital spreadsheets and software programs, it represented the biggest inventory control advancement we had witnessed in centuries. Just a few decades later, mobility is altering the landscape again, as inventory management is untethered from stationary computers and laptops. The benefits of this latest transition are only beginning to be realized.

Mobile capabilities keep teams connected while improving their accuracy and productivity. Access to real-time data and decision making on-the-go bring undeniable convenience, but the greatest benefits come from the competitive advantages gained through mobility.

Let’s explore some of the ways mobile inventory management software can transform your business and enhance your bottom line.

“In my opinion, the future of mobile is the future of everything.” – Matt Galligan

What is mobile inventory management?

Mobile inventory management involves the use of an app to make data and processes related to the inventory management system available on portable devices like tablets and cell phones. Anyone with sufficient permission who has the app installed can get real-time access to this information, wherever they are. This helps bring data and inventory together for processes like cycle counting, order picking, and fulfillment.

The features of a mobile inventory management system include:

- Portability: Inventory management on-the-go allows workers to update information, make decisions, or execute point of sale (POS) transactions from anywhere. Data from brick and mortar, online, and third-party marketplace channels are consolidated on one portable platform.

- Dashboards: Mobile inventory management software should include user-friendly dashboards. These dashboards are typically modeled on the desktop version of the software, with more emphasis placed on commonly used functions to compensate for size constraints.

- Offline access: Unlike traditional inventory management software that is hard-wired to the company network, mobile apps can access data even when the network is down or when employees are working remotely.

- Real-time alerts: Notifications for important events like low inventory levels or expirations can be delivered to users instantly through a mobile app.

- Bar code scanning: Inventory management apps designed to operate on smartphones can integrate QR code scanning through the phone’s built-in camera application.

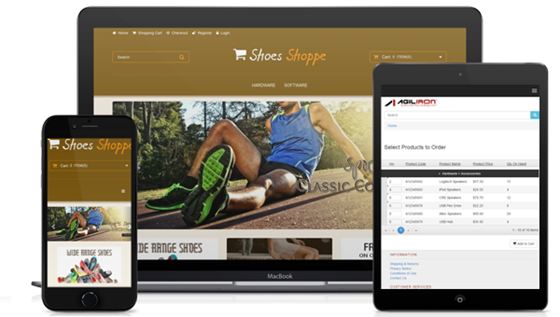

Screenshot of Agiliron’s software

7 key benefits of mobile inventory management

Mobile apps are now essential for a wide range of industries, including transportation, healthcare, retail, and banking; inventory management is another key beneficiary of mobility. The advent of 5G will soon take mobility to the next plateau by supporting enhanced mobile broadband (eMBB) and ultra-reliable low latency communication (URLLC) use cases that deliver higher bandwidth and reduced latency (lag time).

Although the list of mobile inventory management advantages is a long one, these 7 key benefits highlight the undeniable need for mobile applications within any inventory management system:

1. Efficiency

In the past, the daily routine of warehouse workers, manufacturing engineers, purchasing clerks, or supervisors might be filled with excursions to the shop floor or warehouse to collect data using pen and paper, then returning to their desk. Mobile inventory management makes these familiar patterns obsolete by providing a means to easily capture and input inventory data on the go. In addition to this significant productivity benefit, mobile apps also help to improve efficiency by:

- Reducing downtime caused by system access issues

- Expanding decision-making times and locations

- Streamlining inventory auditing practices

- Providing real-time inventory visibility across all locations

2. Minimized hardware costs

Mobile inventory management increases visibility for more workers, including those who would not ordinarily have a dedicated workstation available to them. Despite a reliance on devices to optimize the benefits, adopting a mobile strategy can reduce hardware costs related to:

- Maintenance: Desktop computers and laptops typically require more maintenance than mobile devices to keep them operating smoothly. The purchase price of dedicated computer hardware is also significantly higher.

- Barcode scanning: Mobile devices with integrated barcode scanning capabilities can eliminate the need to install single-purpose barcode scanners throughout the facility or move items long distances to be scanned.

- BYOD Devices: Bring your own device (BYOD) policies allow employees to install company software and apps on their personal devices. Although these policies can reduce upfront hardware costs, the security implications of mixed use devices must be carefully considered.

3. Data accuracy

Bringing the application closer to the materials and processes eliminates the lag between reality on the ground and the data reflected by the system. Automated data input processes, including barcoding systems, reduce errors by decreasing dependence on hand-written notes and other manual forms. When mobile apps send alerts to specific users, a quick resolution of discrepancies and errors will lead to improved data accuracy.

“The ability to take data – to be able to understand it, to process it, to extract value from it, to visualize it, to communicate it – is going to be a hugely important skill in the next decades.” – Hal Varian

4. Improved forecasting

Complete and timely data also leads to better forecasting. Mobile apps improve forecasting practices by enhancing collaboration among employees in different areas of the company and tracking customer order status and fluctuating demand patterns in real time. In some cases, suppliers, including part vendors, external warehouses, and shippers, also tap into the inventory management database using a mobile app. This integration can bolster the flow of real-time data throughout the supply chain.

5. Cloud-based data storage

Cloud-based data and applications are among the keys to device-agnostic inventory management, and the conversion to a cloud-based model also brings other benefits. Cloud-based inventory management eliminates the need to install and expand on-premises hardware and makes the system more scalable as the company grows.

As the number of users increases, cloud-based architecture also makes it easier to push out software updates and security patches to keep processes consistent and data secure.

6. Real-time decisions

Over 28% of the US workforce now works from home or another location outside of the office for at least part of the week. This can make it difficult for decision makers to react to critical inventory situations when they are traveling or do not have direct access to the inventory control database. Mobile inventory management software addresses this issue by sending alerts to decision makers while providing them with the detailed, real-time information they need to proceed.

7. Customer satisfaction

The best way to enhance your bottom line is by enhancing customer satisfaction, and mobile inventory management supports this goal. Mobile processes make it easier to respond to inquiries, input customer orders into the system, and fulfill POS orders more quickly.

Increased mobility also translates to increased visibility. Mobile apps make it possible to track orders through each step of the process and resolve customer issues and errors in real time. Improvements to inventory tracking, cycles counts, and inventory audits also prevent customer service problems like unexpected stock-outs.

Is there a downside?

Including mobile inventory management in your arsenal might seem like a no-brainer, but no system changes are immune to drawbacks. Some potential challenges that must be considered include:

- Implementation costs: The costs associated with new software, devices, and supporting infrastructure can add up, so the expected financial benefits must be weighed against these expenses.

- IT support: Expanding the reach of inventory management also means expanding the number of devices and software applications your IT department needs to support.

- Device security: Mobile devices are prone to loss or theft, which can leave sensitive company and customer data exposed.

- Employee training: Even when mobile apps closely mirror the desktop software interface, their introduction necessitates additional employee training.

Mobility in inventory management is not easy or instantaneous to implement, but the benefits and cost savings far outweigh the drawbacks in the long run.

Mobile inventory management: Final thoughts

Many supply chain companies are already using mobile devices for inventory management, and this trend shows no signs of slowing. What is now being called “Industry 4.0” will see more automation and remote sensing devices used to augment inventory and order management software while taking efficiency and accuracy to unprecedented heights.

Agiliron has embraced mobility as a natural extension of inventory management and customer service. Our mobile Point of Sale (POS) feature allows sales clerks to complete transactions from anywhere, with or without an internet connection. Our updated library of mobile-enabled templates for inventory management and POS solutions is optimized to maintain consistency and brand recognition across mobile and desktop platforms.

Inventory management practices have benefitted from mobile platforms, and the advent of 5G signals a continued reliance on mobility. Schedule a consultation now to learn how to implement or upgrade your mobile inventory management software. Our solution experts are here to help.

Tags: inventory management